PC Tester

Product Details:

- Product Type PC Tester

- Usage Industrial

- Size Standard

- Type PC Tester

- Condition New

- Motor Type AC Motor

- Material MS

- Click to View more

X

PC Tester Price And Quantity

- 1 Unit

PC Tester Product Specifications

- MS

- Standard

- AC Motor

- Industrial

- New

- 220-240 Volt (v)

- PC Tester

- PC Tester

PC Tester Trade Information

- 500 Unit Per Month

- 7 Days

Product Description

1. How to set guide pin reference point - https://youtu.be/4eGAsp-3ksc

2. Examples of defective nut set - https://youtu.be/2xdtMBmu29Y

3. How to install - https://youtu.be/n8mOnoT1Vgw

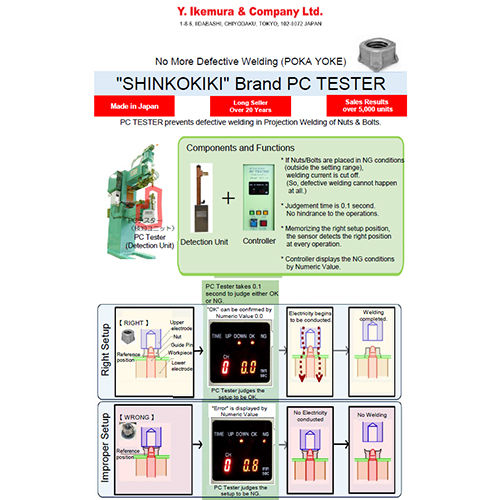

Components and function

- If nuts/ bolts are placed in NG conditions (outside the setting range), welding current is cut off. (so, defective welding cannot happen at all)

- Judgement time is 0.1 second No hindrance to the operations

- Memorizing the right setup position, the sensor detects the right position at every operation.

- Controller displays the NG conditions by Numeric value.

Features:

- Attachable with existing welder easily.

- The lowering margin of the guide pin is detected, and if it is found to be NG (outside the set range), the welding power supply is instantly cut off.

- When NG is detected, the difference from normal times is displayed, and the cause of the error can be identified.

- Air-operated system is used for raising and lowering the guide pin.

- A single-touch for origin alignment.

Functions:

- In case of NG, No current passed. (No welding defects.)

- The judgment time is 0.1 seconds, (No disruption to work.)

- Correct setup position is memorized and the sensor detects the work position each time.

- In case of NG, it is displayed numerically on the controller

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free